Why AGM technology is a must have for modern trucks?

Original equipment manufacturers and logistics companies demand proven high-quality equipment. The VARTA® ProMotive AGM represents a significant breakthrough in commercial vehicle battery development. Using the latest AGM technology, this innovative product meets and surpasses all requirements. But what makes the VARTA ProMotive AGM so unique?

Heavy commercial vehicles have changed significantly over the past years. Advanced fuel saving and comfort-functions along with new governmental regulations and the ongoing changes in driving profiles (reduced driving and extended idle time, and overall more time spent in the trucks) impact the battery in many ways, making high vibration resistance, fast recharging, and a large cycle life along with an increased depth of discharge an absolute must. That is why the VARTA ProMotive AGM is the battery of choice for all major manufacturers when it comes to equipping their commercial vehicles.

Absorbent Glass Mat meets PowerFrame grids

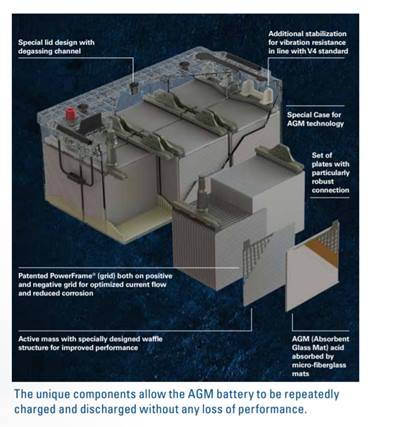

What makes this battery so special? It’s in the name; “Absorbent Glass Mat” or in short “AGM”. This fleece material soaks up the acid in the battery like a sponge, providing the highest cyclic stability. Since there is no acid stratification, the biggest killer of conventional batteries, overall capacity loss is reduced to a minimum, resulting in a much longer life compared to conventional batteries.

A unique feature of VARTA AGM batteries is the patented PowerFrame® design. The VARTA ProMotive AGM is the first battery to use this special grid on both the positive and negative plates for optimum performance and excellent starting characteristics even at low charge levels.

PowerFrame® grid technology is nearly three times* more corrosion resistant than other grid designs and provides more than 60%* superior electrical flow for better connectivity.

Charging cycles and cycle depth

With the increasing number of electrical consumers, the importance of depth of discharge (DoD) is growing. Due to the special design the VARTA ProMotive AGM can be discharged by up to 80% without significantly compromising cycle life, which is a key requirement for state-of-the-art commercial vehicles equipped with fuel saving and advanced hoteling functions. In comparison, for conventional starter batteries a maximum of 20% discharge is recommended to achieve a proper field life.

The cycle life is a crucial performance indicator in energy demanding applications. It defines how many times a battery can be discharged and recharged before it reaches its end of life. The VARTA ProMotive AGM can stand six times more cycles compared to conventional batteries.

With its cycling stability and depth of discharge capabilities AGM is the perfect technology for commercial vehicles that need to supply many electrical consumers during break times and even longer periods like overnight stays.

– This is especially useful for our company. Aside from the usual comfort functions und fuel saving systems, our trucks have fleet telematics on board. It gathers valuable data using a combination of GPS technology, sensors, and onboard diagnostics. All of which must be powered when the truck is driving and parking – explains Krystof Leporowski, Senior Service Technician at Poland-based logistics company Elkor Transport.

Charge acceptance – a critical factor for conventional batteries

– AGM technology allows the batteries to deliver more energy, while at the same time absorbing more charge – meaning this battery will be fully charged within a few hours – says Thorsten Werle, Engineering Design Lead Heavy Duty at Clarios EMEA, referring to another feature of the battery, the charge acceptance.

This is the ability of a battery to accept and store energy considering factors like temperature, state of charge, charging voltage or battery history. The VARTA ProMotive AGM provides a much better charge acceptance than conventional batteries.

That means the battery is recharging faster e.g. a half-discharged AGM battery can be recharged to 90% in only one hour and is fully charged after less than 3 hours of driving. In comparison, a conventional battery needs 2.5 hours to reach the 90% and more than 5 hours for a full charge. These batteries can often not be fully recharged due to the low charge voltage in the vehicles. In comparison to conventional batteries AGM batteries are more efficient with low charge voltage and can be recharged entirely.

That means the battery is recharging faster e.g. a half-discharged AGM battery can be recharged to 90% in only one hour and is fully charged after less than 3 hours of driving. In comparison, a conventional battery needs 2.5 hours to reach the 90% and more than 5 hours for a full charge. These batteries can often not be fully recharged due to the low charge voltage in the vehicles. In comparison to conventional batteries AGM batteries are more efficient with low charge voltage and can be recharged entirely.

A major reason for the gradual deterioration of charge acceptance is acid stratification, which is the accumulation of sulfuric acid at the bottom of the cell. This leads to faster sulfation of the plates, reduced capacity, and hence eventually battery failure. There is no stratification in an AGM and consequently no shift in voltage that goes along with it. With the help of the PowerFrame® design, an AGM generates more than enough power for excellent starting characteristics even if the charge level is low and the depth of discharge is correspondingly high.

Reliable and built to last

In many modern trucks AdBlue tanks and larger fuel tanks are displacing batteries towards the rear end of the frame. In this position, they must be able to withstand increased vibration and shocks but are also stressed by unwanted oscillations and resonances. With conventional technology, the continuous stress can considerably reduce the battery’s life.

– In the past, we had to replace about one third of our batteries due to severe damage. Therefore, we needed more efficient batteries with extended lifetime and reliability – recalls Leporowski.

New requirement for long-distance trucks

For commercial vehicle batteries to meet the requirements of modern long-distance goods transport the European battery standard EN50342 has been revised. The new directive V4 achieves a better approximation to real-life operation. Batteries must now withstand a five-hour vibration test in each three spatial axes over a frequency spectrum from 5 to 100 Hertz. What sounds complicated is basically a test simulating most extreme conditions for batteries in real life. Only a few products on the market have the ability to bound electrolyte, have enhanced fixations and have durable injection molded cases, making them the most robust solution.

Ready for the next generation

VARTA AGM is the manufacturer’s choice when it comes to fitting the best battery technology available – today and in the future.

Leading original equipment manufacturers even consider the VARTA ProMotive AGM for the coming E-Trucks. In full-electric vehicles, the AGM battery plays a major role in supporting the low voltage board net architecture. It supplies the vehicle’s electrical system and secures that safety-relevant functions like lighting, brakes, steering and systems in the cab are working properly even during an outage of the high-voltage-system. For E-Trucks and for future safety systems (like autonomous driving) vehicle manufacturers are convinced that the VARTA ProMotive AGM battery is a perfect fit for these applications.

VARTA Fleet Program: direct contact to the manufacturer

The increasing complexity of modern trucks represents a major challenge for trucking companies. To ensure that fleets are best equipped to cope with these, VARTA has not just developed a reliable, future-ready product in the form of the AGM battery, but also offers the corresponding service with its VARTA Fleet Program. This program’s main feature is that it offers fleet managers direct contact to Clarios.

By registering free of charge on the website www.varta-partner-portal.com/en-GB/fleet-program, members

will receive custom advice relating to their fleet, strategic purchase recommendations, support on battery managementrelated questions, analysis and optimization options for battery performance and a great deal more.

Clarios UK Limited

Suite 5, Building 6, Croxley Park,

Watford Herts WD18 8YH

www.varta-partner-portal.com